Full-Automatic-Puller-Injection-Machine

MASBOND Full-Automatic Puller Injection Machine MS-STM522

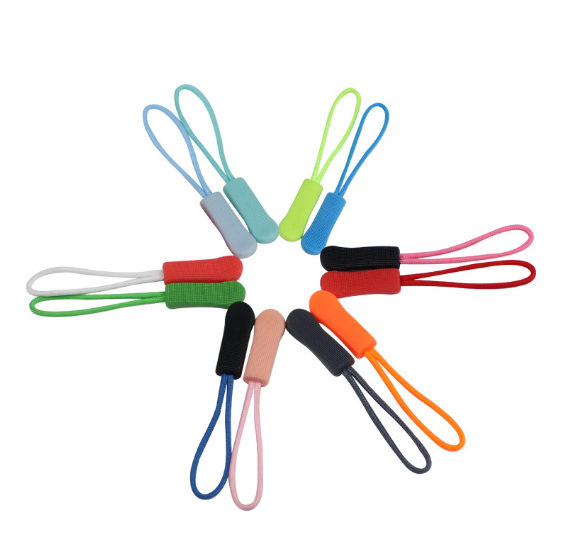

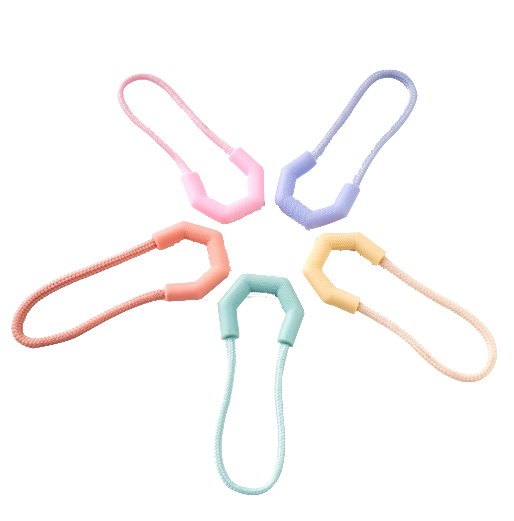

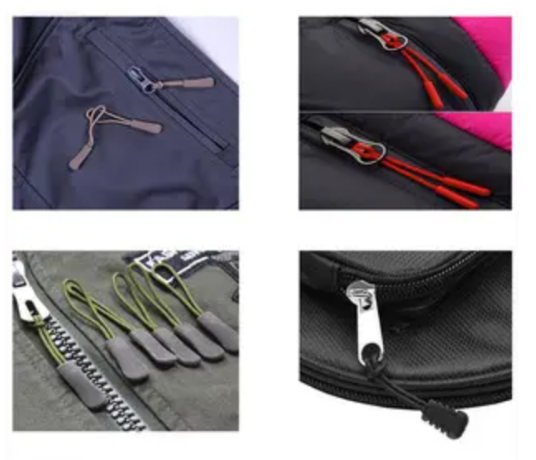

Automatic injection molding of pullers for various garments and bags.

① It can produce 12000-15000pcs everyday

② It is suitable for non-cotton material of the cord

③It cuts the length of rope between 35-90mm

MASBOND Full-Automatic Puller Injection Machine MS-STM522

Overview of MASBOND Full-Automatic Puller Injection Machine MS-STM522:

Fully automatic TPU zipper puller injection molding machine is a specialized injection molding equipment used for producing TPU zipper puller products. TPU (Thermoplastic Polyurethane) is a material known for its excellent abrasion resistance, tear resistance, and flexibility, commonly used in manufacturing high-quality zipper pullers for garments, bags, etc.

Working Principle:

Plastic pellets or granular TPU material are added to the hopper of the injection molding machine.

Through heating and pressure, the TPU material is melted into a liquid state and injected into the mold.

The mold shapes the zipper puller according to design requirements.

Finally, cooling and solidification take place, and the finished product is removed from the mold.

Automation Control:

The fully automatic TPU zipper puller injection molding machine utilizes advanced automation control systems to achieve automated operation throughout the production process. The automation control system can monitor parameters such as temperature, pressure, injection speed, etc., to ensure product quality and production efficiency.

High-Efficiency Production:

The fully automatic TPU zipper puller injection molding machine features high-efficiency production capabilities, enabling continuous and stable production processes. By optimizing the automation control system, production efficiency can be improved, and production costs reduced.

Applicability:

The fully automatic TPU zipper puller injection molding machine is suitable for producing various types of TPU zipper puller products, including different sizes and shapes of pullers.

Adjustability:

Injection molding machines typically have adjustable injection speed, temperature, and pressure to adapt to different types of TPU materials and product requirements.

Quality Control:

The fully automatic TPU zipper puller injection molding machine is equipped with a quality control system that can monitor and adjust key parameters during the production process to ensure stable product quality.

Feature of MASBOND Full-Automatic Puller Injection Machine MS-STM522:、

Full automatic process, automatically pulling rope, placing rope, injection molding, etc., reducing labor production cost.

High efficiency, about 8000-10000 pullers per day.

Digital operation to ensure the accuracy of product quality.

Applicable length 35-90mm.

Technical Parameters of MASBOND Full-Automatic Puller Injection Machine MS-STM522:

| Voltage | 220V | Power | 1.5-2Kw |

| Air Source | 0.5-0.6Mpa | Net Weight | 521kg |

| Ultrasonic Frequency | N/A | Operation Condition | Temperature Range 10-50℃, Humidity of the air 40`60%RH |

| Machine Size | 150*145*180cm | HS Code | 8479400000 |

Get A Quote

Feel free to have a quote on our tapes, we will reply within 48 hours.